The Rise of Home 3D Printing 🏠🖨️

In recent years, the fascination with 3D printing technology has skyrocketed—especially among hobbyists, DIY enthusiasts, engineers, educators, and small business owners.

Once confined to industrial use and specialized labs, 3D printers have now made their way into the modern household—revolutionizing the way we create, repair, and innovate from the comfort of home.

This shift marks an exciting era of digital manufacturing, where creativity meets convenience.

⚙️ Today, owning a 3D printer at home is no longer a luxury—it’s becoming a game-changing investment for personal and professional growth alike.

Whether you’re looking to prototyping unique designs, replace broken household parts, or launch your own custom product business, the benefits of having this powerful tool at your fingertips are undeniable.

But as exciting as it sounds, owning a 3D printer is not without its trade-offs.

That’s why it’s essential to explore both the advantages and the limitations of home 3D printing before making the leap.

This guide will walk you through the most updated and comprehensive insights on the topic, diving into the real 3D printer pros and cons—so you can make a fully informed decision.

🧠 Tip: If you’ve been asking yourself, “Should I buy a 3D printer for home use?”—you’re in the right place.

We’ll help you break it down clearly, weighing all angles from cost, usability, creativity, to environmental impact, so you can decide if it’s truly the right move for you.

🔍 Why Is Home 3D Printing Growing So Fast?

There are a few key reasons why home 3D printing is becoming more mainstream:

- 📉 Prices have dropped significantly: You can now find high-quality desktop 3D printers for under $300.

- 💻 Software has become more user-friendly, even for beginners with no prior design experience.

- 🌍 Online communities, open-source files, and tutorials have made it easier than ever to download and print thousands of pre-made models.

- 🛠️ Customization and repair culture is on the rise, with people printing their own replacement parts, tools, and gadgets.

- 💼 Entrepreneurs are building side-hustles around creating and selling 3D-printed items from home.

This democratization of manufacturing has inspired more people to learn, build, and innovate right from their own desks and garages.

No wonder terms like “desktop 3D printer,” “DIY 3D printing at home,” and “personal 3D fabrication” are gaining traction in search queries!

🧩 What Makes Home 3D Printing So Appealing?

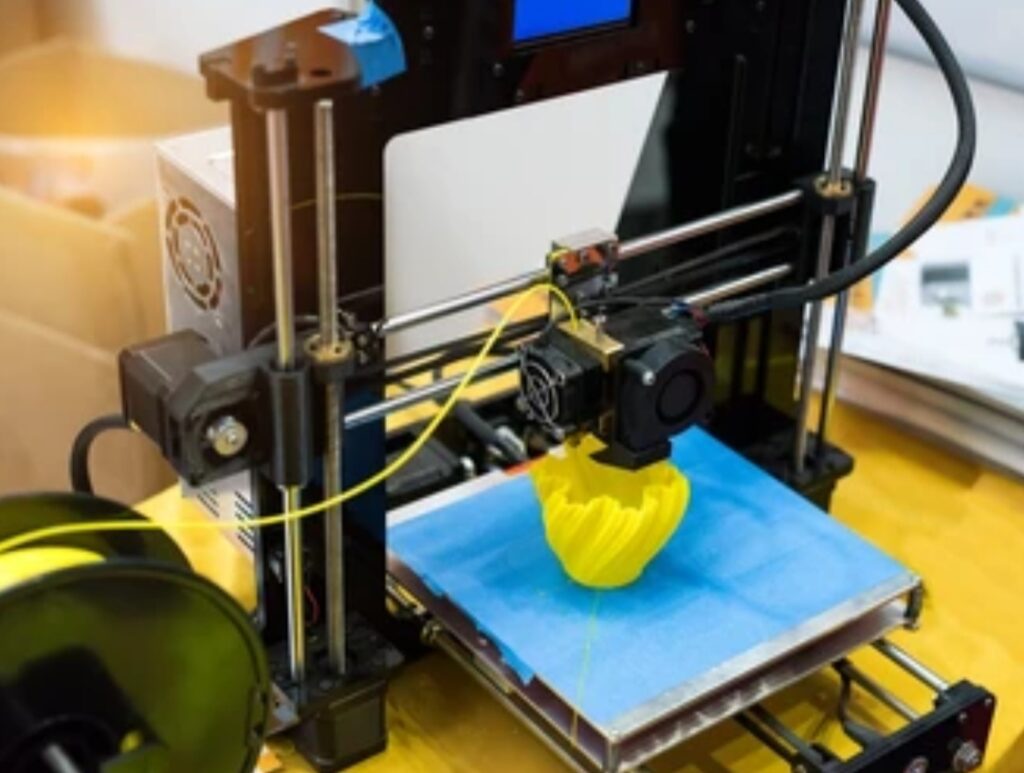

Let’s be real—there’s something incredibly satisfying about designing something digitally and watching it come to life layer by layer on your printer bed.

Whether it’s a quirky key holder, a customized phone stand, a cosplay accessory, or a complex mechanical prototype—you’re limited only by your imagination.

For tinkerers and tech-savvy users, 3D printers offer a level of control and creativity that few other hobbies can match.

But more importantly, they’re no longer just for techies.

With plug-and-play models and a flood of beginner-friendly resources, virtually anyone can join the 3D printing revolution.

👉 Pro Tip: If you’re considering diving in, make sure to check out this beginner-friendly 3D printer model with easy setup and a strong online support community.

⚠️ Why You Should Still Weigh the 3D Printer Pros and Cons Before Buying

Of course, like any powerful technology, 3D printers come with both upsides and downsides.

That’s why understanding the 3D printer pros and cons is crucial if you’re trying to figure out whether it’s a wise investment or a potential dust collector.

Many newcomers dive in headfirst, only to later discover:

- The steep learning curve of 3D modeling software

- Ongoing maintenance and troubleshooting

- Print failures that can be frustrating

- Or even hidden material and electricity costs

Knowing these limitations upfront helps set realistic expectations, so you can make the most of your 3D printer and avoid costly mistakes.

➡️ Keep reading as we break down the honest pros and cons of owning a 3D printer at home, with updated 2025 insights you won’t find in outdated blog posts.

🔥 Is It Right for You? Let’s Find Out.

Our in-depth guide is packed with real-world examples, expert insights, and hands-on tips to help you:

- Determine whether a 3D printer fits your budget and goals

- Understand how to maximize creativity and efficiency

- Avoid common beginner pitfalls

- And decide if you’re ready to take the plunge into home-based 3D fabrication

✅ By the end of this guide, you’ll have a crystal-clear view of whether investing in a 3D printer is a smart decision or something best left on your wishlist.

Don’t make a move without reading this.

👉 Scroll down to uncover the truth about the pros and cons of owning a 3D printer at home! 💥

What Is a 3D Printer and How Does It Work? 🖨️⚙️

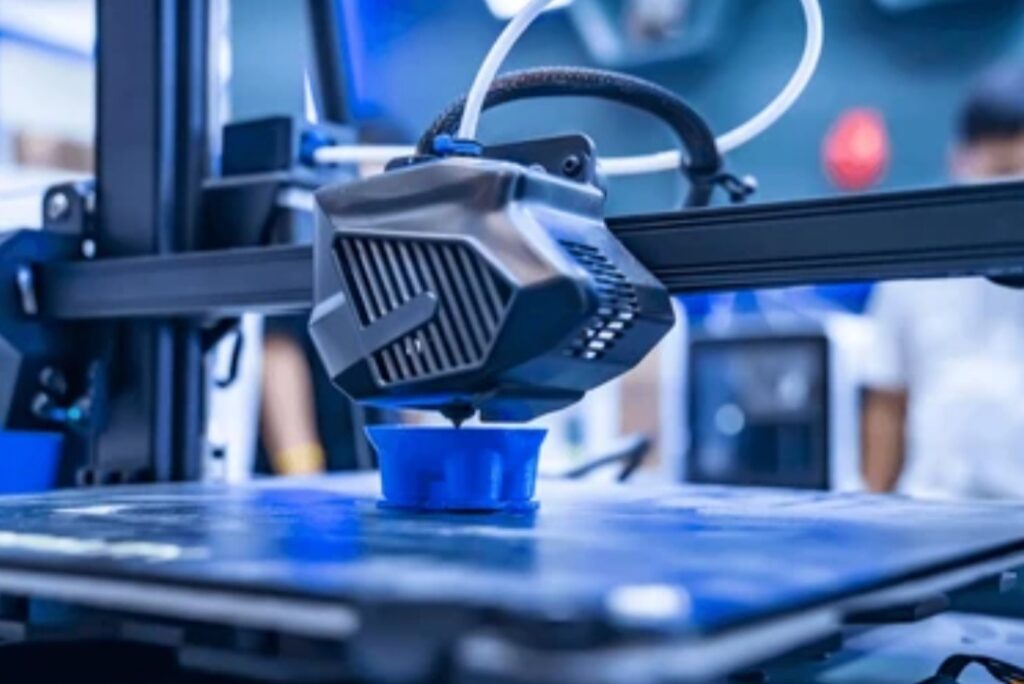

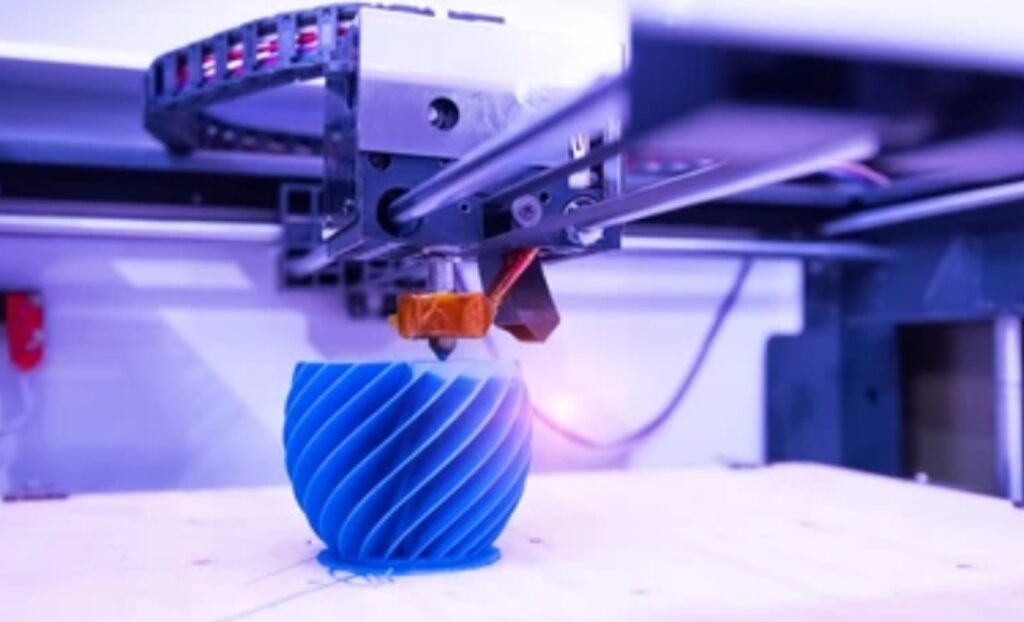

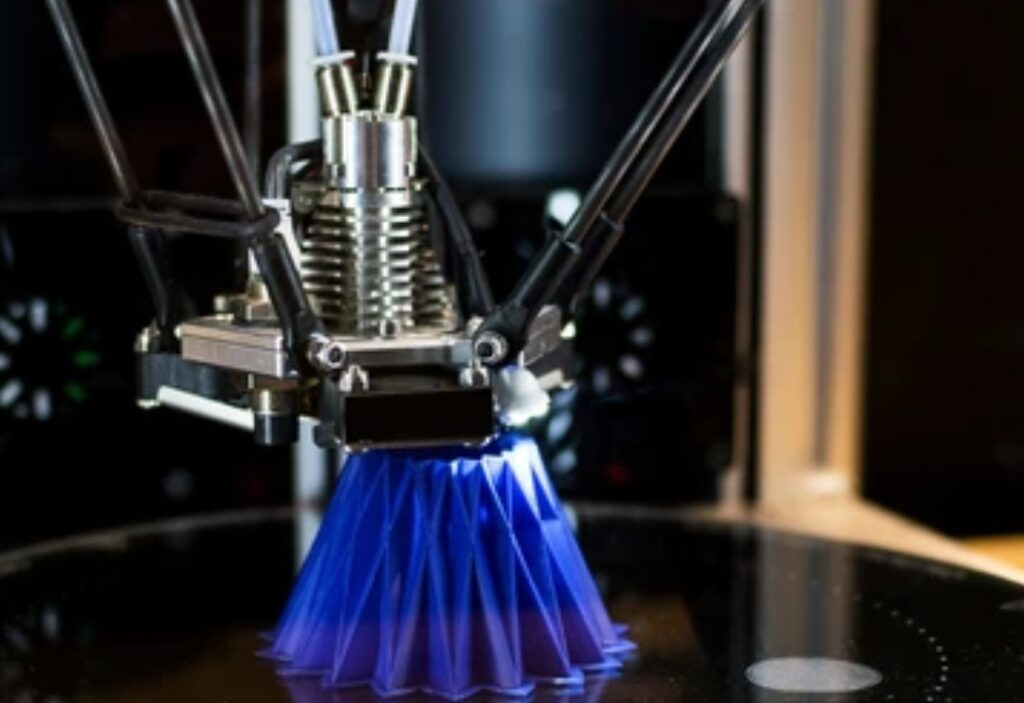

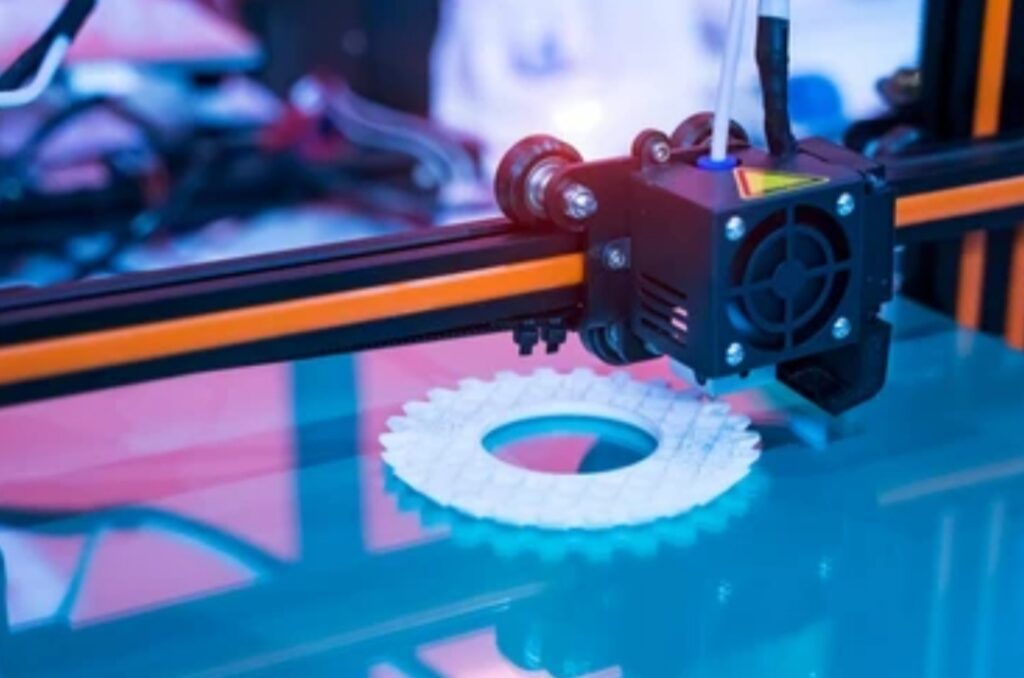

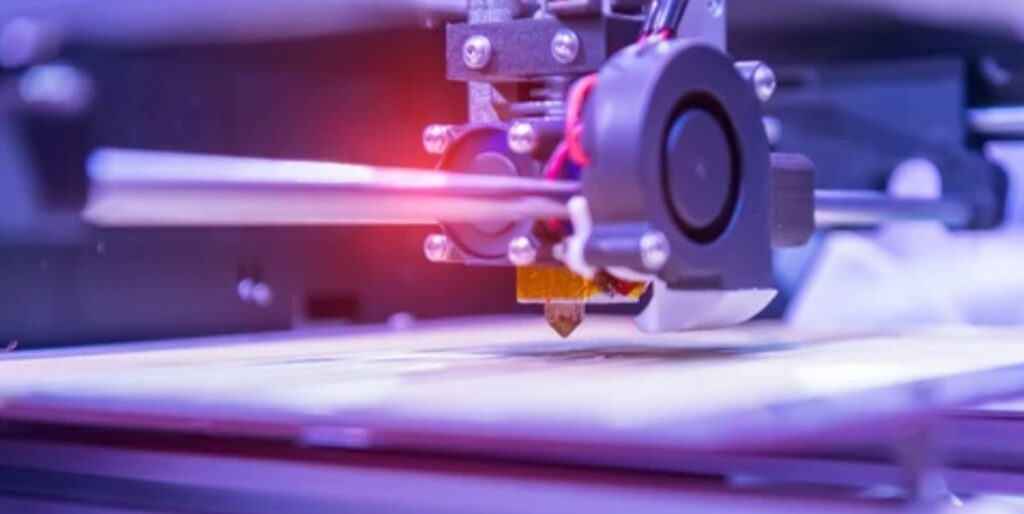

In the simplest terms, a 3D printer is a machine that creates three-dimensional objects by layering materials based on digital designs.

Unlike traditional manufacturing methods, which often involve cutting, drilling, or molding, 3D printing builds objects from the ground up—layer by layer—using what’s known as an additive manufacturing process.

This process has revolutionized the way we create physical products—allowing everyday users to produce custom parts, prototypes, art, tools, toys, and more, right from their homes.

If you’re thinking about getting into DIY 3D printing, it’s essential to understand how the machine functions before weighing the full 3D printer pros and cons.

🔬 The Basic Anatomy of a 3D Printer

Most desktop 3D printers for home use share the same core components:

- Extruder/Hotend 🔥 – This is the part that melts the filament and deposits it in layers. Think of it like a high-tech glue gun.

- Build Plate 🧱 – The surface where the object is printed. Some are heated to help the material stick better during the process.

- Stepper Motors ⚙️ – These control the precise movements of the extruder along the X, Y, and Z axes.

- Filament Feeder 🎯 – This feeds the printing material (typically a plastic filament) into the hotend.

- Control Panel or Touchscreen 🖥️ – This allows users to adjust settings, start prints, and monitor progress.

- Frame 🧩 – The structure that holds all parts together, ensuring stability and accuracy.

Once you understand these components, you’ll realize that while 3D printers may seem intimidating, their operation is based on logic, precision, and digital control.

🛠️ How Does a 3D Printer Actually Work?

Here’s a step-by-step breakdown of how most FDM (Fused Deposition Modeling) printers work—the most common type used in homes:

🧾 Step 1: Design Your Object Digitally

You begin by creating a 3D model using CAD software like:

- Tinkercad (great for beginners)

- Fusion 360

- Blender

- SketchUp

Alternatively, you can download thousands of pre-designed models from free sites like Thingiverse, Printables, or MyMiniFactory.

🧠 Tip: Beginners can start with simple models like keychains or phone stands to learn the ropes without frustration.

📐 Step 2: Slice the Model Using a Slicer Program

Before your printer can understand the design, it needs to be converted into G-code—a set of instructions the printer follows.

This is done using a slicer software like:

- Ultimaker Cura

- PrusaSlicer

- Bambu Studio

- Creality Slicer

Slicing lets you adjust settings such as:

- Layer height

- Print speed

- Infill density

- Supports

🎯 Step 3: Start the Print

After slicing, you transfer the file to your printer (via SD card, USB, or Wi-Fi), heat the printer, load the filament, and hit print.

The printer will then:

- Heat the filament (usually PLA, PETG, or ABS)

- Extrude it onto the build plate

- Repeat the process layer by layer until the object is finished

Depending on complexity, prints can take anywhere from 30 minutes to 24+ hours.

🧵 Types of 3D Printers You Might Use at Home

To better understand the 3D printer pros and cons, it helps to know that not all 3D printers are created equal.

Here are the two main types popular for home use:

1️⃣ FDM (Fused Deposition Modeling)

This is the most common and beginner-friendly type.

- Uses spools of filament (like PLA or PETG)

- Great for functional parts, prototypes, and toys

- Affordable and widely supported

✅ Pros: Cheap material, easy maintenance

❌ Cons: Lower resolution than resin printers

2️⃣ SLA or Resin Printers (Stereolithography)

Uses liquid resin cured with UV light to produce incredibly detailed prints.

- Best for miniatures, jewelry, dental models, and highly detailed parts

- Requires post-processing (washing and curing)

✅ Pros: Ultra-high resolution

❌ Cons: Messier, more expensive, needs ventilation

🧠 Is 3D Printing Complicated for Beginners?

Honestly, it depends on your willingness to learn.

While plug-and-play models exist, 3D printing has a learning curve—especially when it comes to:

- Troubleshooting failed prints

- Fine-tuning temperature settings

- Leveling the bed manually (though many printers now offer auto bed leveling)

- Understanding filament types

But the good news? Online communities, YouTube tutorials, and user forums are incredibly active and supportive.

💡 Pro Tip: If you’re just starting, go for a model like the Creality Ender 3 V3 or Anycubic Kobra 2—both known for affordability, reliability, and easy learning.

🧑🏫 3D Printing Terms You Should Know

Here’s a quick glossary to help you navigate:

| Term | Meaning |

| PLA | A beginner-friendly filament made from corn starch |

| Infill | The density inside the object (more = stronger) |

| Support | Temporary structures used for overhangs |

| G-code | The language your printer understands |

| Nozzle | The part where filament exits onto the build plate |

| Raft/Brim | Structures to help prints stick better |

✅ Final Thoughts on How 3D Printing Works

Understanding how a 3D printer works is the first step toward deciding if it’s right for you.

Once you get the hang of it, 3D printing becomes an incredibly empowering tool—whether you’re looking to start a side hustle, replace broken parts, or bring creative visions to life.

But remember: It’s not magic.

It’s a combination of tech, learning, patience, and a bit of trial and error.

👉 Keep reading to discover the most important pros and cons of owning a 3D printer at home—so you can decide whether it’s worth the hype in 2025.

The Pros of Owning a 3D Printer at Home 🏠✨

Owning a 3D printer at home opens up a world of creativity, independence, and cost savings—and that’s just the beginning.

Whether you’re a hobbyist, entrepreneur, teacher, or tech enthusiast, the advantages of having a 3D printer in your own space can be truly transformative.

Let’s explore the major benefits in detail, with examples and real-world use cases to help you decide if the investment is worth it.

💡 (Keep reading—some of these pros might surprise you!)

💰 1. Save Money on Custom and Everyday Items

3D printing isn’t just a cool hobby—it’s a cost-cutting powerhouse.

Instead of buying replacement parts, accessories, or gadgets online, you can simply print them at home.

Examples of things you can print and save on:

- Phone holders and stands 📱

- Drawer organizers and storage racks 🧺

- Wall hooks, hinges, and door stoppers 🚪

- Custom keychains, cases, and clips 🔑

- Broken appliance knobs and parts 🔧

🔥 Power Tip: Many users report saving hundreds of dollars a year by printing custom parts that would otherwise be expensive or hard to find.

🎨 2. Endless Customization and Creative Freedom

3D printers let you become the designer, the engineer, and the creator—all at once.

You’re no longer limited by what stores sell. Want a phone stand with your initials? A cookie cutter shaped like your logo? A personalized dog tag for your pup?

Print it.

Creative Use Cases:

- Personalized gifts for friends and family 🎁

- Customized board game pieces and dice 🎲

- Themed decorations for birthdays and holidays 🎉

- Cosplay props and wearable accessories 🦸♀️

- Functional art and modern sculptures 🎨

With a 3D printer, the only limit is your imagination.

🎯 Want to turn your creativity into cash? You can also sell your custom prints on platforms like Etsy, eBay, or Facebook Marketplace.

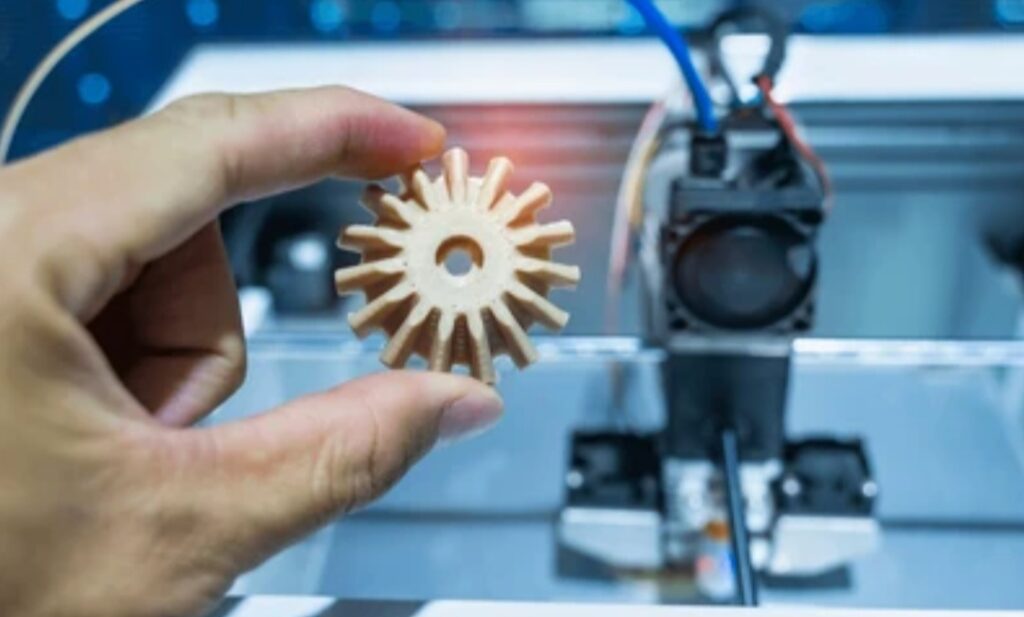

🚀 3. Rapid Prototyping and Innovation

This is a game-changer for entrepreneurs, engineers, and inventors.

With a 3D printer, you can go from idea to physical product in hours—instead of weeks or months.

No waiting for manufacturers. No need for expensive molds. Just design → slice → print → test.

Perfect for:

- Product designers validating ideas 💡

- Engineers testing mechanical parts 🔩

- Startup founders creating MVPs 🧠

This flexibility gives you a huge edge, especially if you’re bootstrapping.

📈 Real-World Example: Many Kickstarter founders used home 3D printers to build their prototypes before raising funds!

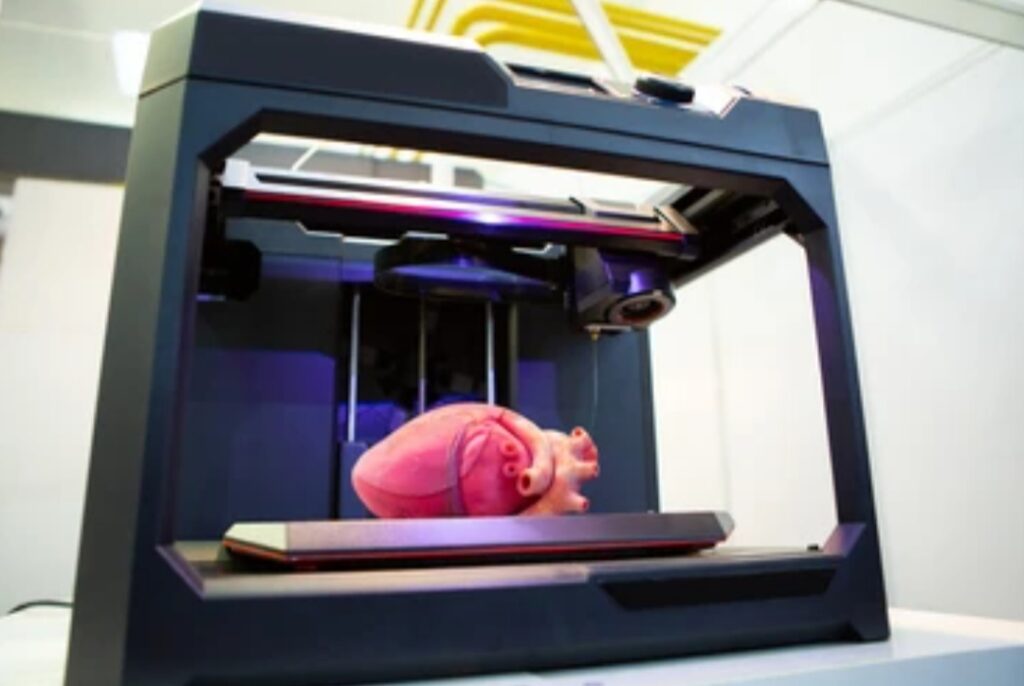

🧠 4. Educational Value and Skill Development

Whether for kids, teens, or adults, 3D printing is one of the best hands-on tools for learning STEM.

It teaches:

- Problem-solving and troubleshooting

- Engineering basics

- Design thinking

- CAD modeling skills

Schools and homeschoolers are now using 3D printers to teach:

- Geometry through model building 📐

- History through replica artifacts 🏺

- Biology through 3D-printed organs 🫀

🤓 Did You Know? Some parents use 3D printers to make their child’s school projects stand out (think volcanoes, dioramas, and working models!).

🕹️ 5. Endless Fun for Hobbyists and Tinkerers

If you love gadgets, electronics, or crafts, owning a 3D printer at home is pure joy.

You can print parts for drones, RC cars, keyboard mods, and even Arduino enclosures.

Hobbyists love using 3D printers for:

- Model building 🛩️

- Miniature painting 🎨

- Warhammer terrain creation 🧱

- DIY electronics 💡

🎮 Pro Tip: Combine your 3D printer with a laser engraver, soldering kit, or CNC for the ultimate maker’s workstation. Insert recommended accessory here

🛠️ 6. Convenient Repairs and Replacements

We’ve all been there: a broken clip, missing screw, or out-of-stock part that’s holding everything up.

With a 3D printer:

- You can print it.

- You can fix it.

- You can stop wasting money on full replacements.

Whether it’s a broken curtain hook, a washer for your faucet, or a bracket for your cabinet, you can download or design the file and have a working solution in hours.

🧰 Pro Tip: Join communities like Reddit’s r/3Dprinting or Thingiverse groups for help finding or modifying parts.

🌍 7. Environmental Benefits: Reduce Waste

3D printing can be a more sustainable way to make things compared to traditional manufacturing.

You only use as much filament as needed—reducing scrap material.

Some advanced users also recycle their old prints or failed jobs into fresh filament using a filament recycler.

♻️ Eco-Friendly Practices:

- Use PLA filament (biodegradable)

- Reuse support material when possible

- Print only what you need

💡 Want to reduce your carbon footprint? 3D printing is a step toward a greener, DIY lifestyle.

🛍️ 8. Start a Side Hustle or Small Business

If you’re looking for a low-cost business idea, a 3D printer can be your golden ticket.

Thousands of makers are already:

- Selling customized products online

- Printing on-demand orders for clients

- Offering local repair and prototyping services

📦 Popular Niche Products to Sell:

- Customized keychains 🔑

- Pet tags 🐾

- Gaming accessories 🎮

- Miniature terrain 🗿

- Home décor 🪴

💡 Power Tip: Pair your printer with a free design tool like Tinkercad and an eCommerce platform like Shopify or Etsy to launch fast.

👉 Start your own print-on-demand shop today with just a printer, some filament, and your imagination!

✅ Why So Many People Are Buying 3D Printers for Home Use

From financial savings and creative expression to educational impact and eco-friendly living, the benefits of owning a 3D printer at home continue to grow in 2025.

It’s not just a tool—it’s a gateway to independence, innovation, and income.

Still, like all technology, it comes with challenges.

Keep reading for a brutally honest breakdown of the downsides of 3D printing at home—because making an informed choice means knowing the 3D printer pros and cons in full.

The Cons of Owning a 3D Printer at Home ⚠️💸

While the benefits are exciting, it’s only fair to shine a spotlight on the challenges and limitations that come with owning a home 3D printer.

Understanding the 3D printer pros and cons thoroughly will help you make a smarter, more informed decision—especially before you invest your hard-earned money.

Below, we’ll break down the real-world drawbacks, frustrations, and common pitfalls that many users face.

💥 Important: These aren’t deal-breakers—but they do require attention and preparation.

💸 1. High Initial Cost and Long-Term Expenses

Let’s be honest—3D printing isn’t cheap, especially if you want a reliable setup.

Upfront costs include:

- The printer itself (ranging from $250 to $1,000+)

- Filament (PLA, ABS, PETG, etc.)

- Spare parts (nozzles, hot ends, beds)

- Tools and accessories (scrapers, calipers, glue sticks)

But it doesn’t stop there…

👉 Ongoing expenses can sneak up on you:

- Replacing worn-out parts

- Upgrading firmware or hardware

- Buying premium filament for better quality

- Paying for CAD software or STL files

💡 Tip: Budget at least $50–$100/month for upkeep and materials, especially if you print frequently.

🔧 2. Steep Learning Curve and Troubleshooting Issues

Owning a 3D printer at home is not plug-and-play.

Many first-time users are surprised to find:

- Prints failing halfway through

- Bed adhesion problems

- Stringing, warping, or under-extrusion

- Error messages and firmware bugs

🧠 You’ll need to learn:

- Slicing software (Cura, PrusaSlicer, etc.)

- Bed leveling and nozzle calibration

- Temperature tuning

- Support structure settings

📚 Power Tip: Join forums like r/FixMyPrint or Discord communities for fast help and real-time advice.

⚙️ If you’re not ready to dive into trial-and-error learning, 3D printing can become frustrating fast.

🐢 3. Slow Print Speeds (Patience Required!)

Despite all the tech advancements, 3D printing is still slow.

Even small objects can take 2–6 hours to finish. Larger or detailed items? Expect overnight prints—or longer.

🕓 Example:

- Phone stand: 4 hours

- Figurine: 8+ hours

- Helmet prop: 20+ hours

And if the print fails halfway… you’ll have to start over from scratch 😓.

🕵️♂️ Pro Tip: Use time-lapse features or OctoPrint to monitor long prints remotely.

😖 4. Print Failures Are Common (and Annoying)

Not every print comes out perfect.

In fact, most beginners face 20–30% failure rates early on.

You may deal with:

- Layer shifting

- Clogged nozzles

- Curling edges

- Bed adhesion failures

- Print spaghetti 🍝 (yes, that’s a real thing)

💡 Reality Check: You will waste some filament, some time, and a lot of patience while learning.

But don’t worry—it gets better with experience.

🧽 5. Post-Processing Can Be Time-Consuming

After a print is done, you’re not always finished.

Many models need:

- Support removal 🪓

- Sanding and filing 🔧

- Gluing parts together 🔩

- Priming and painting 🎨

This adds time and effort—especially if you want clean, professional-looking results.

⏱️ Tip: Factor in an extra 30 minutes to 2 hours per print for finishing touches.

🎯 If you want “print and go,” be prepared for disappointment.

📢 6. Noise and Odor (Not Always Family-Friendly)

Some printers are quiet—but others sound like tiny construction sites 👷♂️.

Noisy fans, motors, and stepper movements can be irritating, especially in bedrooms or shared living spaces.

Also, certain filaments like ABS emit unpleasant fumes. Without proper ventilation, they can cause headaches or irritation.

Best Practices:

- Use an enclosure or sound dampening box 🎧

- Keep printers in garages, offices, or ventilated rooms

- Avoid printing overnight in the same room you sleep in

🌬️ Tip: Invest in an air purifier if you’re using fume-heavy filaments. Insert recommended air purifier

🔥 7. Safety Risks and Maintenance Requirements

3D printers use heated elements, moving parts, and sometimes high voltages.

This isn’t a toy—it’s a machine that requires care.

Common hazards:

- Burns from heated nozzles or beds

- Electrical shorts from DIY upgrades

- Fire risks from unattended prints

🔥 Important: Always supervise long prints. NEVER leave your 3D printer running when you’re not home.

And yes—you’ll need to:

- Clean the nozzle

- Replace PTFE tubing

- Check belts and pulleys

- Re-calibrate the bed regularly

✅ Weighing the 3D Printer Pros and Cons Like a Pro

As you can see, owning a 3D printer at home is a double-edged sword.

✔️ On one hand, it offers amazing opportunities for creativity, DIY repairs, and even side hustles.

❌ On the other, it demands time, money, and a willingness to learn from your failures.

💡 So what’s the verdict?

If you’re excited to learn, patient with trial and error, and ready to experiment—you’ll love it.

But if you’re looking for plug-and-play simplicity or hands-off automation, you might want to wait until the technology gets more user-friendly.

🧭 Is a 3D Printer Right for You?

Before you buy, ask yourself:

- Am I willing to learn slicing, calibration, and design?

- Do I have the budget for accessories and upgrades?

- Am I excited about printing functional or artistic items?

- Can I handle failed prints without rage-quitting? 😂

If the answer is yes to most of these…

🎯 Then yes—a 3D printer might be one of the best investments you’ll ever make.

👉 Ready to dive into the world of 3D printing?

Check out the best starter 3D printers here

and start building the future—right from your desktop. 💻🖨️

Comparative Analysis: 3D Printing vs. Traditional Manufacturing 🏭🖨️

When evaluating the 3D printer pros and cons, it’s essential to understand how this revolutionary technology stacks up against traditional manufacturing methods like injection molding, CNC machining, and casting.

This comparison will help you assess whether a 3D printer fits your personal or business needs—and how it can enhance or replace conventional techniques.

Below is a detailed head-to-head breakdown to help you make an informed decision 👇

🏎️ Speed and Production Time

Traditional Manufacturing

✅ Once set up, processes like injection molding or stamping produce items in seconds

🚧 However, setup time can take days or even weeks—especially for molds or dies

💰 Best suited for mass production where thousands of units are needed

3D Printing

⏳ Slower per unit (prints can take several hours)

✅ But zero setup time—just design, slice, and print

🧠 Ideal for rapid prototyping, one-offs, and low-volume runs

⚡ Summary:

- If you need fast high-volume production, traditional methods win

- For fast-to-market prototypes or limited quantities, 3D printing dominates

💰 Cost-Effectiveness (Short-Run vs. Mass Production)

Traditional Manufacturing

💸 High upfront costs (tooling, mold creation, factory equipment)

✅ Very low cost per unit once mass production begins

⚠️ Not cost-efficient for small batches or individual products

3D Printing

🔧 Low initial investment—no molds, just a printer and filament

📦 Economical for small runs, one-off items, and custom projects

⚠️ Not ideal for mass-producing thousands of identical parts

💡 Power Insight: For entrepreneurs or DIYers creating custom tools, spare parts, or gadgets, home 3D printing is far more affordable in the short term.

🎯 Design Flexibility and Customization

Traditional Manufacturing

🛠️ Limited flexibility once molds or tools are made

❌ Complex geometries often require multiple manufacturing steps or custom tooling

✅ Great for standard, uniform products

3D Printing

💥 Complete design freedom—complex geometries, internal structures, and organic shapes are easy to achieve

🔄 Perfect for on-demand personalization (e.g., custom phone cases, medical implants, cosplay props)

🎨 Key Takeaway: If your business thrives on customization, 3D printing gives you a serious competitive edge.

🌍 Sustainability and Waste Reduction

Traditional Manufacturing

❌ Often subtractive (CNC machining cuts away material) = lots of waste

🌱 High energy use and material loss

♻️ Recycling is possible but not always cost-effective

3D Printing

✅ Additive process = only uses the material required

♻️ Many filaments are recyclable or biodegradable (e.g., PLA)

🌍 Lower carbon footprint for small production runs

🧠 Eco-conscious creators and brands can use 3D printing to build a greener supply chain.

🏡 Accessibility and Ease of Entry

Traditional Manufacturing

🏢 Requires access to factories, workshops, or outsourcing partners

🧾 You may deal with contracts, shipping delays, and minimum order quantities

3D Printing

🖨️ Print from your own desk, garage, or home office

🎓 Tons of free resources to learn and improve (YouTube, forums, GitHub, Thingiverse)

📦 On-demand production without relying on third-party vendors

⚡ Want to start your own product line or launch a prototype?

Get a reliable beginner 3D printer here and take control of your entire production process.

🔄 Maintenance and Operational Complexity

Traditional Manufacturing

🧰 Requires skilled operators, maintenance engineers, and high-precision machines

🛠️ Long downtimes if something breaks

3D Printing

🧼 Home printers need light maintenance—cleaning nozzles, replacing hot ends, bed leveling

📉 No formal training needed—you learn as you go

🔍 Bottom Line: Home 3D printers are more user-friendly than you think—especially with newer models designed for beginners.

🧪 Prototyping and Innovation Speed

Traditional Manufacturing

🚧 Prototype development is slow and expensive

📆 Iteration cycles take weeks or months

3D Printing

🚀 Print → Test → Modify → Reprint (within hours or days)

💡 Encourages fast innovation, especially for inventors, students, and engineers

🛠️ Pro Insight: Brands like Ford, Nike, and Boeing use 3D printing to prototype faster than ever.

You can too—from your home lab.

🧾 Quick Comparison Table

| Feature | Traditional Manufacturing | 3D Printing (Additive) |

| Setup Time | Long (molds, dies) | Very short |

| Cost per Unit (Low Qty) | High | Low |

| Cost per Unit (High Qty) | Low | Higher |

| Customization | Limited | Unlimited |

| Material Waste | High | Low |

| Production Volume | High-scale | Small-to-medium scale |

| Ease of Use | Requires professionals | Accessible to consumers |

| Speed to Prototype | Slow | Fast |

| Upfront Investment | High | Low to Medium |

| Design Freedom | Low to Medium | Very High |

✅ Which One Should You Choose?

It’s not about which method is better—it’s about which one fits your goals.

- Need mass production? Go traditional.

- Need flexibility, innovation, and on-demand production?

3D printing is your game-changer.

For hobbyists, entrepreneurs, educators, and creators—home 3D printing opens up a world of possibilities.

🔥 Ready to experience the freedom of creating from home?

Browse top-rated 3D printers for beginners**

and take the first step toward becoming your own manufacturer. 🛠️💡

Best Use Cases for Home 3D Printing in 2025 🏡✨

Home 3D printing has come a long way in recent years—what was once a novelty is now a practical tool for makers, small business owners, and creative hobbyists alike.

If you’re wondering whether owning a 3D printer is worth it, understanding its real-world applications is key to evaluating the 3D printer pros and cons.

Let’s dive deep into the most popular, profitable, and practical use cases for home 3D printing in 2025 and beyond 🧵📦🧠

🛠️ Rapid Prototyping for Inventors and Entrepreneurs

Home 3D printers are an absolute game-changer for product development.

You can take an idea from your head to your hands—within hours.

There’s no need to wait weeks for a prototype from an overseas manufacturer.

Whether you’re designing tools, gadgets, or a new kitchen accessory, 3D printing accelerates the innovation cycle dramatically.

This means you can test, improve, and validate your idea faster than your competitors.

Try printing your first prototype with a basic FDM printer and see how quickly your concepts take shape.

🧩 Educational Tools for Students, Teachers, and Parents

3D printers are transforming how we teach science, technology, engineering, arts, and math—aka STEAM education.

Teachers are using them to demonstrate real-world physics principles.

Students design and print custom models to learn geometry or build working mechanical systems.

Parents can supplement their children’s education with hands-on projects that are both educational and fun.

Need a custom DNA strand model or a topographical map of Mount Everest?

Print it in hours.

This is why many schools are investing in desktop 3D printers for classroom innovation.

🖼️ DIY Crafts, Art, and Home Decor Projects

Are you into home décor, painting, cosplay, or jewelry design?

3D printing empowers artists to create one-of-a-kind masterpieces without outsourcing production.

Print customized vases, wall art, cosplay armor, miniatures, and even designer furniture pieces.

Want a lamp that matches your aesthetic perfectly?

Design it, print it, and paint it—all from your living room.

This is a massive win for creators who want to offer limited-edition or signature designs on Etsy or Shopify.

Check out affordable filament options for artistic prints to start crafting today.

🔩 Household Repairs and Functional Parts

Lost a knob on your stove?

Need a bracket to hold up your shelf?

With a 3D printer, you can replace missing or broken parts in a matter of hours—no need to hunt through hardware stores or wait for Amazon delivery.

From curtain rod clips to charging cable organizers, home 3D printing saves time and money by creating functional solutions.

This is one of the most underrated 3D printer pros—the ability to solve everyday problems with custom-designed fixes.

You can find thousands of free templates for common household items on sites like Thingiverse, Printables, or Cults3D.

🧠 Assistive Devices and Personalized Medical Tools

Need a phone stand that clips to your wheelchair?

Or an ergonomic grip for a pen?

3D printers allow people to design and build assistive devices tailored to individual needs.

This is especially valuable for physical therapists, occupational therapists, and caretakers who require custom tools on a budget.

You can even print adaptive utensils, hearing aid holders, or braille learning kits at home.

This democratization of healthcare tools is one of the most impactful uses of 3D printing in 2025.

🎮 Gaming Accessories and Miniatures

If you’re a fan of Dungeons & Dragons, Warhammer, or video games, a home 3D printer opens up endless possibilities.

Print your own custom dice towers, game tokens, terrain maps, or figurines.

You’re no longer limited to what’s available in stores—you can create fully personalized gaming experiences.

Plus, tabletop gamers often turn this into a side hustle by selling their creations online.

Download STL files for top-rated game models here and start building your fantasy world today.

📦 Small Business Production and Print-on-Demand

Tired of outsourcing products and dealing with minimum order quantities?

You can run a small print-on-demand business right from your garage or home office.

Sell cookie cutters, phone stands, planters, or mechanical parts—design once, and print as needed.

With tools like Etsy, Shopify, and Gumroad, creators can launch a business in days without holding inventory.

This lean model is one of the most popular 3D printer use cases for solopreneurs.

Start your side hustle with a reliable printer here and print your first product tonight.

🐾 Custom Pet Products

Yes, even your furry friends can benefit from 3D printing.

Print custom dog tags, cat toys, slow-feeder bowls, or pet door latches.

Pet owners love personalized accessories—and 3D printing makes it easy and cheap to create one-of-a-kind items.

Bonus: If you’re a pet brand, you can test product ideas before going to mass production.

⚙️ Robotics, Engineering & Automation Projects

If you’re into electronics, Raspberry Pi, or Arduino, 3D printing will become your best friend.

Create enclosures, robotic arms, mounts, and brackets tailored to your build.

Combine it with motors, servos, and microcontrollers for endless DIY projects.

This is a huge area of growth in 2025, as automation and home robotics become more accessible.

Join any maker group, and you’ll see 3D printing is the go-to tool for every engineer or tinkerer.

🧼 Soap Molds, Cookie Cutters & Kitchen Gadgets

Kitchen makers and bakers love the ability to print custom molds, tools, and utensils.

Want a cookie cutter shaped like your dog? Done.

Need a soap mold with your business logo? Easy.

These niche items often sell at a premium on craft marketplaces.

This is one of the best ways to monetize your 3D printer if you’re into baking or beauty products.

🧠 Summary of 2025’s Best Home 3D Printing Uses

- ✅ Rapid prototyping for product development

- ✅ Education and learning aids

- ✅ DIY art, cosplay, and custom decor

- ✅ Functional household repairs and gadgets

- ✅ Assistive devices and custom medical tools

- ✅ Gaming accessories and models

- ✅ Small business production and ecommerce

- ✅ Custom pet accessories

- ✅ Robotics and electronics projects

- ✅ Kitchen and crafting tools

💥 Ready to turn your ideas into reality?

Get started with a beginner-friendly 3D printer today**

and explore a world where you design, create, and profit—all from home. 🛠️🚀

Materials You Can Use with Home 3D Printers (and What They’re Best For) 🧱🖨️

Choosing the right material for your 3D print is crucial to the success of your project.

3D printer pros and cons depend heavily on the materials you use because different materials offer different properties, including strength, flexibility, and heat resistance.

In this section, we’ll dive into the most common materials for home 3D printing and explain what each one is best suited for.

By the end, you’ll know which filament or resin fits your needs, whether you’re creating functional parts, art pieces, or prototypes.

🧃 PLA (Polylactic Acid) – The Beginner’s Favorite

PLA is the go-to material for beginners due to its ease of use, availability, and affordability. It’s made from renewable resources like cornstarch or sugarcane, making it eco-friendly and biodegradable.

Pros of PLA

- Easy to print: Works well even on entry-level 3D printers

- Low odor: Unlike some filaments, PLA doesn’t emit harmful fumes

- Bright finish: Produces smooth, shiny prints with vibrant colors

- Eco-friendly: Biodegradable and made from renewable sources

Cons of PLA

- Brittle: Not ideal for high-impact applications

- Low heat resistance: Starts to deform around 60°C (140°F)

- Not ideal for outdoor use: Will degrade under UV exposure

Best Uses for PLA

- Prototypes and models

- Decorative objects and toys

- Small, low-stress functional parts like phone stands or planters

For beginners and hobbyists, PLA is often the go-to filament for creating beautiful, easy-to-manage prints.

Shop PLA filament here for your next creative project.

⚙️ ABS (Acrylonitrile Butadiene Styrene) – Durable and Heat-Resistant

ABS is a popular filament in industrial applications due to its toughness and durability. It’s commonly used for automotive parts, electrical enclosures, and consumer goods.

Pros of ABS

- Strong and durable: Perfect for functional parts that require impact resistance

- Heat resistant: Can withstand higher temperatures than PLA (up to 100°C or 212°F)

- Flexible: Can be used for slightly flexible parts

- Good for post-processing: Can be smoothed using acetone to create a glossy finish

Cons of ABS

- Difficult to print: Requires higher temperatures (250°C+) and a heated bed

- Odor: Emits fumes during printing that can be unpleasant (proper ventilation needed)

- Warping: Prone to warping without proper print settings or a heated bed

Best Uses for ABS

- Functional parts like gears, knobs, and brackets

- Parts exposed to high heat (automotive parts, electrical housings)

- Toys and models that need durability and strength

For more experienced users, ABS provides strength and reliability for tough, functional prints.

Find premium ABS filaments here to print your next project.

🌿 PETG (Polyethylene Terephthalate Glycol) – The Tough Hybrid

PETG is an excellent middle ground between PLA and ABS. It combines the best qualities of both, offering durability, flexibility, and heat resistance without many of the difficulties of ABS.

Pros of PETG

- Tough and impact-resistant: Perfect for functional prototypes or parts that need to take a beating

- Flexible: More flexible than PLA without compromising strength

- Food-safe: Can be used to make containers for food, though proper cleaning is necessary

- Easy to print: Works well on most 3D printers with a heated bed

Cons of PETG

- Stringing: Can sometimes leave unwanted strings between parts due to its sticky nature

- Prone to scratching: Not as resistant to wear and tear as ABS

Best Uses for PETG

- Durable functional parts like mechanical components

- Containers and packaging that require strength and impact resistance

- Outdoor objects due to its UV resistance

PETG is perfect for DIY projects and small business owners who need tough, reliable prints.

Shop PETG filaments here and start printing your next durable product.

🧪 Resin – Ultra-High Detail for Small Parts

Resin printing is a method that uses liquid resin hardened by UV light to create highly detailed prints. Resin printers typically offer much higher resolution than FDM printers, making them ideal for jewelry, miniatures, and prototypes that require precision.

Pros of Resin

- Ultra-high detail: Perfect for miniatures, jewelry, or parts requiring fine details

- Smooth finish: No layer lines, resulting in a sleek, glossy surface

- Wide range of materials: Flexible, tough, castable, and even biocompatible resins available

Cons of Resin

- Messy: Requires post-processing like cleaning with alcohol and curing under UV light

- Brittle: Some resins can be more brittle than FDM filaments

- Toxicity: Requires proper ventilation and safety precautions, as resin fumes can be harmful

Best Uses for Resin

- High-detail models like miniatures, figurines, and jewelry prototypes

- Dental molds and medical applications (biocompatible resins)

- Parts with intricate geometries that need to be precise

If you’re focused on high-quality details and small-scale prints, resin printing is your ideal choice.

Browse the best resin printers here and start creating intricate designs.

🧳 TPU (Thermoplastic Polyurethane) – Flexible and Rubber-Like

TPU is a flexible material used to create soft, rubber-like parts. It’s commonly used for phone cases, watch bands, and custom gaskets due to its elasticity and wear resistance.

Pros of TPU

- Flexible: Can be stretched and bent without breaking

- Wear resistant: Perfect for parts that need to endure friction, like shoe soles or seals

- Shock absorbing: Ideal for protective gear or parts exposed to impact

Cons of TPU

- Difficult to print: Requires slower print speeds and a direct-drive extruder

- Not ideal for very fine details: Not as precise as hard plastics like PLA or resin

Best Uses for TPU

- Protective cases (phone cases, wearables)

- Gaskets and seals

- Footwear and accessories that require flexibility

For anyone needing flexible parts, TPU is a must-have material in your 3D printing toolbox.

Shop TPU filament here for your flexible 3D prints.

🧱 Choosing the Right Material for Your Project

Selecting the right material is the key to achieving the best 3D print quality for your specific needs.

- For beginners, PLA is a great starting point due to its ease of use.

- ABS is best for functional, durable parts that need to withstand heat.

- PETG offers the best of both worlds, combining durability and ease of printing.

- Resin is perfect for high-precision details.

- TPU is essential for flexible and shock-resistant parts.

Understanding each material’s pros and cons will help you make informed decisions based on your projects and goals.

🔥 Ready to take your 3D printing to the next level?

Shop the best 3D printer materials here

and unlock endless possibilities with your home 3D printer! 🏡🔧

The Future of Home 3D Printing: Trends to Watch in 2025 and Beyond 🔮🏡

As 3D printing technology rapidly evolves, the potential for home-based manufacturing is expanding at an astonishing rate. What started as a hobbyist trend has transformed into a powerful, accessible tool for creators, small business owners, and tech-savvy households.

In this section, we explore the exciting future of home 3D printing—highlighting emerging trends, innovative advancements, and how these changes will impact the 3D printer pros and cons going forward.

🚀 AI-Powered Design and Print Optimization

One of the most groundbreaking developments in the future of 3D printing is the integration of artificial intelligence (AI).

AI is transforming the design and printing process by:

- Optimizing print settings automatically for perfect results

- Identifying design flaws before printing begins

- Predicting print failures in real-time, saving time and material

- Enhancing model slicing with smarter algorithms

This technology makes 3D printing more beginner-friendly by reducing the learning curve, which is often considered one of the cons of owning a 3D printer.

AI integration means more reliable prints, higher quality output, and less trial and error—an undeniable pro for future users.

🧠 Smart 3D Printers and IoT Connectivity

Smart 3D printers are becoming increasingly connected to the Internet of Things (IoT).

Expect to see:

- Remote print monitoring via apps or browsers

- Cloud-based slicing software that allows for on-the-go design edits

- Voice-activated controls and real-time system diagnostics

These smart features make it easier for users to print efficiently and securely, whether they’re at home or away.

The ability to troubleshoot or pause a print from your phone is a major step toward making home 3D printing more convenient and foolproof.

♻️ Rise of Eco-Friendly Filaments and Sustainable Printing

Sustainability is a massive concern across all industries—and 3D printing is no exception.

Future developments are focusing on:

- Recyclable materials and bio-based filaments (like algae-based PLA)

- In-printer recycling systems to reuse failed prints or leftover filament

- Energy-efficient printers designed for home use

These advancements aim to reduce the environmental footprint of 3D printing, making it a more sustainable hobby or business.

💡 Pro Tip: Start switching to recycled PLA or PETG to lower your impact while keeping print quality high.

Find eco-friendly filaments here to support greener 3D printing.

🖨️ Multi-Material and Full-Color Printing

One of the biggest upcoming game-changers is multi-material and multi-color printing.

Imagine creating a fully functional product in one go—combining rigid, flexible, and conductive parts without assembly.

In 2025 and beyond, we expect:

- More affordable dual-extruder home printers

- Automated filament switching during prints

- Color blending capabilities for detailed, vivid prints

This feature will push creative boundaries and reduce production steps, transforming the way we build products at home.

✅ This is one of the biggest “pros” on the horizon for home 3D printer owners.

📈 More Use Cases for Everyday Consumers and Professionals

3D printing is no longer limited to just enthusiasts. The future opens the door to practical uses for almost everyone:

- Educators printing STEM models and learning tools

- Makers and artists creating high-end collectibles

- Entrepreneurs designing product prototypes or even selling goods on Etsy

- DIYers fabricating replacement parts or home gadgets

The accessibility and usefulness of 3D printers continue to grow, making the “cons” of learning the tech more and more outweighed by the benefits.

🧬 Bioprinting, Food Printing, and the Cutting Edge

Though still in the early stages for home use, the long-term future holds even more advanced possibilities:

- Bioprinting for creating tissue models (eventually even organs!)

- Food printers capable of printing custom chocolates, pasta, or pancakes

- Printable electronics for building DIY circuit boards and gadgets at home

These innovations are paving the way for 3D printers to become an essential appliance in modern households—much like microwaves or coffee machines.

Explore next-gen 3D printers here that are leading this revolution.

Embrace the 3D Printing Revolution

The future of home 3D printing is incredibly bright, with developments making the technology more accessible, powerful, and sustainable than ever.

Here’s a recap of what’s ahead:

- AI and smart tech will make printing easier and faster

- Eco-friendly materials will make it greener

- Multi-material capabilities will expand creativity

- Everyday consumers will benefit more than ever

If you’re still deciding whether to invest, consider this: the gap between professional-grade and home-use 3D printers is closing fast.

The pros are growing, and the cons are shrinking—especially with smarter tech and better materials on the horizon.

💥 Don’t wait for the future — start printing it now!

Discover the top home 3D printers of 2025

and take your creativity to the next level today! 🚀🖨️

Tips for Prospective 3D Printer Owners 🛠️🧠

If you’re considering buying your first 3D printer, you’re not alone. With the rise of affordable models, user-friendly software, and countless online resources, now is one of the best times to explore 3D printing at home.

But before you hit that “Buy Now” button, there are critical tips every prospective 3D printer owner should know.

These tips will help you make an informed decision, avoid beginner mistakes, and get the most value from your investment—especially when weighing the 3D printer pros and cons.

Let’s break it down so you can start smart, print smarter.

🎯 Understand What You Want to Print First

The first and most important step is to define your purpose.

Ask yourself:

- Are you printing functional objects like phone holders, door stops, or mechanical parts?

- Do you want to create detailed miniatures, cosplay gear, or artwork?

- Are you planning to sell items or use them in a business?

This decision affects everything—from printer type to material selection.

For example:

- If you need smooth surface detail for figurines, a resin (SLA) printer might be best.

- If you need tough, mechanical parts, a FDM printer with strong filament like PETG or ABS is a better choice.

🎯 Tip: Match your goals to the right printer before you invest.

🔍 Research Different Types of 3D Printers

There are two main types of consumer 3D printers:

- FDM (Fused Deposition Modeling) – Melts plastic filament to build layer by layer. Best for beginners and functional prints.

- SLA (Stereolithography or Resin Printing) – Uses UV light to cure liquid resin. Ideal for ultra-detailed, smooth prints.

Here’s a quick comparison:

| Feature | FDM | SLA |

| Cost | Lower | Moderate |

| Detail | Good | Excellent |

| Mess/Cleanup | Low | High |

| Smell | Minimal | Strong resin odor |

| Ideal For | Prototypes, parts | Miniatures, jewelry |

🧠 Explore the best beginner 3D printers here based on your specific needs.

🧰 Choose the Right Filament (Materials Matter)

Your printer is only as good as the material you feed into it.

Common filament types:

- PLA: Great for beginners, low warping, eco-friendly

- PETG: Stronger than PLA, more durable

- ABS: Heat-resistant but more difficult to print

- TPU: Flexible, rubber-like prints

- Resin: Used for SLA printers, delivers high detail but requires safety precautions

✅ Tip: Start with PLA to get used to the basics—it’s forgiving and prints beautifully.

Also, store your filament properly in airtight containers with desiccant to avoid moisture issues.

⚙️ Don’t Underestimate the Learning Curve

While 3D printing is fun and rewarding, it’s also not completely plug-and-play—especially at the start.

Prepare to learn:

- Basic 3D modeling or downloading files from platforms like Thingiverse or Printables

- How to level the bed properly

- How to troubleshoot failed prints (you will have them!)

- Basic maintenance like cleaning nozzles and calibrating belts

It’s a steep but satisfying journey—think of it as learning a new instrument.

📌 Pro Tip: Join online forums like Reddit’s r/3Dprinting or Facebook groups to get real help from real users.

💸 Budget for More Than Just the Printer

Many beginners only consider the printer’s price. But you’ll need other essentials, too.

Consider budgeting for:

- Extra filament or resin

- Tools: Scrapers, pliers, nozzle cleaners

- Spare parts: Nozzles, hot ends, print beds

- Upgrades: Enclosures, auto bed leveling, build plates

- Post-processing tools: Sandpaper, resin wash & cure stations

💡 A $300 printer can quickly become a $450+ project if you’re serious about quality and consistency.

🧼 Safety First – It’s Not Just Plug and Print

Whether you’re using FDM or resin, safety is non-negotiable.

For FDM Printers:

- Ventilation is important, especially when using ABS or exotic filaments

- Heated beds can reach over 100°C – keep kids and pets away

- Use a fire-safe location and never leave prints unattended overnight

For Resin Printers:

- Always wear gloves and eye protection

- Cure prints thoroughly to avoid toxicity

- Dispose of resin waste responsibly—it’s hazardous

🧯 Pro Tip: Set up your printer on a fireproof mat in a well-ventilated area and install a smoke detector nearby.

💡 Start with Pre-Tested Models

Avoid jumping into 3D modeling from scratch.

Platforms like:

- Thingiverse

- Printables by Prusa

- Cults3D

- MyMiniFactory

…offer thousands of free and paid designs that are already tested by the community.

Downloading proven models ensures:

- Better print success rates

- Less frustration for beginners

- A smoother learning curve

🚀 Pro Tip: Look for “beginner-friendly” tags and read the comments to avoid time-wasting mistakes.

🧠 Take Notes & Document Your Journey

Want to improve fast?

Track your prints:

- Which settings worked

- What filament you used

- What went wrong (and how you fixed it)

This is especially helpful when dialing in tricky filaments or changing environmental conditions.

📝 Keep a log or even start a mini blog to document your 3D printing journey. It’s rewarding and helpful for others, too.

📦 Be Patient, Be Curious, Be Bold

Owning a 3D printer at home opens up endless possibilities, but it’s important to enter this world with realistic expectations.

Yes, there are pros and cons—but the opportunities to learn, create, and innovate far outweigh the early challenges.

🛠️ Learn as you go.

🧠 Stay curious.

🚀 Don’t be afraid to experiment.

✨ The magic of creating something from nothing is just a few layers away.

💥 Ready to dive into the world of 3D printing?

Explore our top-rated starter kits and must-have tools for beginners

and take the first step into a world of unlimited creativity! 🎨🖨️

Frequently Asked Questions (FAQs) 🤔📌

Looking for quick answers about owning a 3D printer?

Here are the most frequently asked questions, answered in plain English to help you make smarter decisions.

Whether you’re comparing the 3D printer pros and cons, curious about costs, or wondering about real-life use cases—this section covers it all.

❓ Is owning a 3D printer worth it?

Yes, for many hobbyists, creators, and small business owners, owning a 3D printer is worth it.

It offers creative freedom, customization, and cost-saving opportunities over time.

However, it comes with a learning curve, upfront costs, and occasional technical issues—so it’s essential to weigh the 3D printer pros and cons before buying.

💰 How much does a 3D printer cost for home use?

Most beginner-friendly 3D printers cost between $150 to $500.

Mid-range machines can range from $500 to $1,000, while high-end or industrial options can go above $2,000.

Don’t forget to factor in the cost of filament, spare parts, tools, and maintenance—budgeting at least $100 to $200 extra for accessories and consumables is wise.

🧵 What materials can a 3D printer use?

The most common 3D printing materials include:

- PLA (easy to print and eco-friendly)

- ABS (strong and heat-resistant)

- PETG (durable and versatile)

- TPU (flexible and rubbery)

- Resin (for detailed prints in SLA printers)

Different printers are compatible with different materials, so check your machine’s specs before choosing a filament or resin.

🛠️ How difficult is it to learn 3D printing?

For beginners, 3D printing can feel challenging at first—but with patience and practice, it becomes manageable and even fun.

You’ll need to learn how to level the bed, adjust settings, troubleshoot print failures, and maybe even some basic 3D modeling.

Luckily, there are plenty of online communities, YouTube tutorials, and guides to help you every step of the way.

🧽 Is a 3D printer messy or dangerous?

FDM printers are relatively clean and safe if used properly, but they still involve high temperatures and moving parts.

Resin printers, on the other hand, are messier and require more safety precautions—gloves, masks, ventilation, and careful cleanup are essential.

Always follow the manufacturer’s safety guidelines and never leave a 3D printer unattended for long periods.

📦 Can I use a 3D printer to make money?

Absolutely—many users turn their 3D printers into profitable side hustles or even full businesses.

You can create and sell custom prints, cosplay gear, home decor, replacement parts, or even digital STL files online.

Sites like Etsy, eBay, and Gumroad are great platforms for monetizing your 3D printing skills.

👉 Check out beginner-friendly 3D printing business ideas here.

🏡 Can I use a 3D printer inside my home or apartment?

Yes, most home 3D printers are safe for indoor use—especially FDM printers using PLA.

Make sure the area is well-ventilated, especially when using materials like ABS or resin, which can produce unpleasant or even harmful fumes.

Consider placing the printer in a dedicated room, garage, or enclosed workspace for better noise and odor control.

🧾 Are there ongoing costs with owning a 3D printer?

Yes—owning a 3D printer means you’ll regularly spend money on:

- Filament or resin

- Nozzles and parts replacement

- Adhesives, build plates, or cleaning supplies

- Electricity usage (minor but worth noting)

While cost per print is generally low, you should plan for monthly maintenance and restocking costs if you print often.

⚖️ What are the biggest pros and cons of 3D printing at home?

Pros include:

- Creative freedom

- Customization

- Cost-saving on replacement parts

- Educational value

- Potential income opportunities

Cons include:

- Learning curve

- Failed prints and trial-and-error

- Equipment maintenance

- Ongoing material costs

- Safety concerns with certain materials

Understanding these 3D printer pros and cons will help you decide if it’s right for your lifestyle and goals.

🧠 Can kids use 3D printers?

Yes—but only under adult supervision.

Some printers are marketed as kid-friendly, but even beginner machines get very hot and involve moving parts.

If you’re introducing a child to 3D printing, consider starting with:

- Pre-assembled printers

- Beginner filaments like PLA

- Supervised projects using files from trusted sources

🎓 Bonus: 3D printing can be an incredible STEM learning experience for kids and teens!

💡 Still have questions?

Drop your question in the comments or contact us directly—we’re happy to help guide you on your 3D printing journey!

💥 Ready to start printing?

Click here to find the best beginner 3D printer bundles and exclusive deals today!

Conclusion: Is a Home 3D Printer Right for You? 🤖🏠

After exploring the 3D printer pros and cons in depth, you’re probably wondering: Is a home 3D printer the right investment for me?

Let’s break it down one last time.

Owning a 3D printer opens the door to creativity, self-sufficiency, and potential income.

You can bring your ideas to life, prototype your inventions, or replace broken parts around the house—all from the comfort of your home.

For tech enthusiasts, makers, hobbyists, educators, and even small business owners, a 3D printer can be a total game-changer.

But it’s not all smooth printing.

There are also real challenges like:

- A steep learning curve in the beginning

- The need for ongoing maintenance and material costs

- Occasional frustration with failed prints or tech glitches

- Space, noise, and safety considerations—especially with resin printers

So, is it worth it?

✅ Yes—if you’re curious, creative, willing to learn, and see value in printing things yourself.

❌ Maybe not—if you prefer plug-and-play convenience or don’t want to tinker with settings and machines.

The answer depends on your goals, budget, and how much time you’re willing to invest in learning.

But here’s the good news:

With so many affordable and beginner-friendly printers on the market today, it’s easier than ever to dip your toes into this powerful technology.

And as the 3D printing industry continues to evolve, home users now have access to tools that were once limited to professionals and engineers.

✨ In short: A home 3D printer can be incredibly rewarding—if you walk in informed, patient, and ready to explore.

💥 Ready to start your 3D printing journey today?

Click here to explore top-rated beginner 3D printers and starter kits now!

Or, if you’re still unsure, check out our ultimate beginner’s guide to choosing your first 3D printer for even more expert tips.

You might also like :